JUST-BIN System Transport

JUST-BIN System TransportThis system improves the efficiency of logistics by eliminating transportation redundancy by delivering packages from multiple customers together consolidated service.

High quality and low cost of the just in time system is achieved.

JUST-BIN System Warehouse

JUST-BIN System WarehouseFocusing on polymer products, high quality and low cost is achieved with a storage capacity of 1,314,980 ft2 across 10 centers, 3 automated warehouses with 8,446 pallets, and 8 centers with movable racks and 49,861 pallets.

Through Distribution

Through DistributionThis system receives and sorts the products that arrive in the day from early in the morning without storing at the warehouse and sends the products for secondary distribution in a timely manner.

Cost reduction is achieved by cutting the storage cost.

D-3PL (DAISEI-Third-party Logistics)

D-3PL (DAISEI-Third-party Logistics)The knowledge of JUST-BIN is leveraged to coordinate and provide customers with optimized logistics.

Change in Packaging of Polymer Products

Change in Packaging of Polymer ProductsThe packing of polymer products can be changed to paper bags and flexible containers depending on the weight or the convenience of the delivery destination.

Slitting Process for wrapping film

Slitting Process for wrapping filmThe center dealing with films has its own slitters with slit function reducing the labor and cost.

Eco System

Eco SystemThe vehicles that delivery the products of the customers, picks the recycled products of the customers.

Vehicle Movement Management System at internet

Vehicle Movement Management System at internetWe can respond to urgent needs of our customers by collectively managing the real-time vehicle location information.

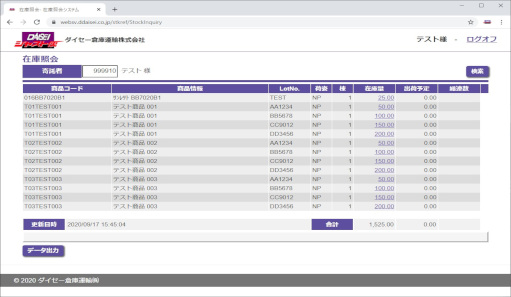

Online Inventory Status System

Online Inventory Status SystemThe inventory and history of products entrusted to us can be directly verified.

Activities to Implement the Services

Activities to Implement the ServicesDaisei W&T implements many different activities to implement the day-to-day services for customer.